Best Wood Finishes for DIY Projects

Understanding Different Finish Types

The world of wood finishes offers something for every project and preference. Traditionalists swear by linseed oil's warm glow, while modern crafters appreciate water-based polyurethane's quick drying time. Each option brings unique benefits:

- Oil-based finishes deepen wood's natural beauty but require patience

- Water-based options offer low odor and easy cleanup

- Wax provides subtle protection with a hand-rubbed feel

My neighbor learned this lesson the hard way when his lacquered outdoor bench peeled after one winter. Environment matters as much as aesthetics.

Preparing the Wood for Finishing

Nothing ruins a finish faster than skipping prep work. I start every project with 220-grit sandpaper, working up to 400-grit for silky smoothness. Pro tip: wipe surfaces with mineral spirits to reveal hidden flaws before finishing. Those invisible scratches will glare at you after staining.

Remember my disastrous first attempt? I skipped grain filling on oak and wound up with a pockmarked surface. Now I keep wood filler in my toolkit alongside these essentials:

- Tack cloth for dust removal

- Putty knife for gap filling

- Sandpaper in multiple grits

Applying the Finish Correctly

Application technique separates amateurs from pros. I learned this watching a cabinetmaker work - his brush strokes followed the grain in perfect, unhurried motions. Three golden rules I now follow religiously:

- Thin coats beat thick globs every time

- Maintain wet edges to prevent lap marks

- Resist the urge to overbrush

That last one cost me two sanding-and-restart cycles on my first dresser project.

Finishing Techniques and Tools

The right tools transform finishing from chore to craft. After ruining brushes with oil-based poly, I invested in quality natural bristle brushes for oils and synthetic for water-based products. My toolkit includes:

- Foam brushes for delicate work

- China bristle brushes for oils

- Microfiber cloths for wipe-on finishes

Game-changer discovery: using a paint strainer removes those annoying bubbles from polyurethane.

Maintaining Your Finished Wood

My grandmother's walnut table still gleams because she taught me proper care. For oil finishes, monthly conditioning with beeswax keeps wood nourished. Polyurethane? A damp cloth and occasional polish does the trick. The cardinal sin: using furniture polish on wax finishes - it creates gummy buildup.

When my nephew spilled juice on my oak desk, this quick fix saved the day:

- Blot (don't rub!) the spill

- Clean with mild soap solution

- Reapply wax to the affected area

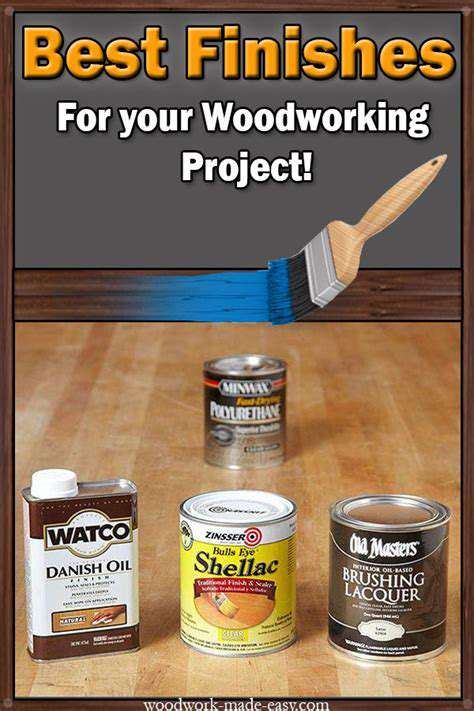

Popular Wood Finishes for Beginners and Experienced Crafters

Choosing the Right Finish for Your Project

Selecting a finish feels overwhelming until you consider three key factors: durability, appearance, and skill level. My first mistake was choosing an advanced finish for a simple shelf - the results looked amateurish. Beginners should master these forgiving options first:

- Tung oil for small projects

- Wipe-on polyurethane for furniture

- Gel stains for even coloring

Oil-Based Stains

Nothing beats oil stains for enhancing wood's character. I use them on projects where I want the grain to sing, like this cherry bookcase. Critical safety note: always work in ventilated areas and dispose of rags properly - they can spontaneously combust!

My favorite oil stain trick: applying a pre-stain conditioner prevents blotchiness on softwoods like pine.

Water-Based Stains

When my wife complained about solvent smells, I switched to water-based options. They've come a long way - modern formulas offer richer colors than early versions. Biggest advantage: cleaning brushes with soap and water instead of mineral spirits.

Pro tip: raise the grain with water before staining to avoid surprises later.

Polyurethane Finishes

For high-traffic pieces like kitchen tables, polyurethane is my go-to. The water-based version dries crystal clear, while oil-based adds warm amber tones. Secret for flawless application: sand lightly between coats with 320-grit paper.

I learned this technique from a furniture restorer: thin the first coat 50/50 with mineral spirits for better penetration.

Lacquer Finishes

Lacquer remains the finish of choice for professional-looking results. Spray applications produce glass-smooth surfaces, but require proper equipment. Warning: lacquer fumes are extremely flammable - I only use it in my well-ventilated garage.

When I refinished my guitar, lacquer delivered that perfect glossy sheen.

Sheen Levels and Their Impact

Sheen selection affects both appearance and maintenance. My dining table sports satin polyurethane - glossy enough to impress but matte enough to hide fingerprints. Designer trick: use different sheens to create visual interest, like matte tops with semi-gloss legs.

Safety Precautions for Beginners

After getting polyurethane in my eye (lesson learned!), I never work without safety glasses. My workshop checklist includes:

- NIOSH-approved respirator

- Chemical-resistant gloves

- Fire extinguisher

Non-negotiable rule: no open flames near finishing materials - not even pilot lights!

Finding medical specialists reminds me of choosing finishes - expertise matters. A sleep medicine certified doctor understands nuances like different finish types require specialized knowledge. Just as I research wood products, patients should verify credentials.

![How to Play [Specific Card Game, e.g., Bridge]](/static/images/34/2025-05/AdvancedStrategiesandTechniques.jpg)