Guide to Building Advanced Lego Structures

Employing Specialized LEGO Elements

Exploring Specialized Technic Elements

LEGO Technic sets offer a unique opportunity to delve into the world of advanced mechanical principles. These sets often incorporate specialized elements like gears, axles, and various types of motors, allowing builders to create intricate mechanisms and functional models. Understanding how these specialized elements interact and work together is crucial for successfully building complex Technic models and appreciating their engineering prowess. Mastering the use of these elements is a key step in progressing to more advanced LEGO building techniques.

Utilizing Specialized Plates and Tiles

Beyond the standard bricks, LEGO offers a wide array of specialized plates and tiles. These components often come in unique shapes and sizes, providing design flexibility for creating detailed architectural models or intricate landscapes. The subtle variations in plate and tile designs can dramatically change the aesthetics and functionality of a structure, enabling builders to achieve a higher level of detail and precision in their creations. Careful consideration of these specialized components is essential for building structurally sound and aesthetically pleasing models.

Implementing Specialized Connectors and Joints

LEGO's specialized connectors and joints are essential for creating robust and stable structures. These elements allow for the construction of intricate angles, complex linkages, and strong connections between different components. Choosing the appropriate connector or joint is vital for ensuring that the model can withstand stress and maintain its shape. Experimenting with different types of connectors and joints is a great way to expand your understanding of structural principles in LEGO building.

Understanding how these elements are designed to maximize strength and minimize stress points is important in creating robust and stable structures.

Mastering Specialized Pneumatic and Hydraulic Systems

For even more advanced builds, LEGO offers specialized pneumatic and hydraulic systems. These elements allow builders to create models with moving parts and functional mechanisms, such as excavators, cranes, or even simple robots. Understanding the principles behind these systems is crucial for controlling and directing the movement of the parts. These specialized systems introduce a deeper level of engineering and problem-solving into the LEGO building process.

Advanced LEGO Display and Storage Solutions

Preserving your meticulously crafted LEGO creations is just as important as building them. Specialized display and storage solutions are available, ranging from custom-designed stands to elaborate showcases. These solutions allow you to showcase your work in a professional manner and keep your collection safe and organized. Proper storage and display techniques are crucial for maintaining the value and appeal of your LEGO creations.

Applying Advanced Color and Pattern Coordination

Beyond structural elements, the use of color and pattern coordination plays a significant role in advanced LEGO building. Careful selection and placement of colors and patterns can enhance the visual appeal of a structure and create a cohesive design. This aspect of LEGO building often involves an element of artistry and creativity, allowing builders to express their personal style and preferences. Using color schemes effectively can dramatically impact the overall aesthetic appeal of a LEGO project.

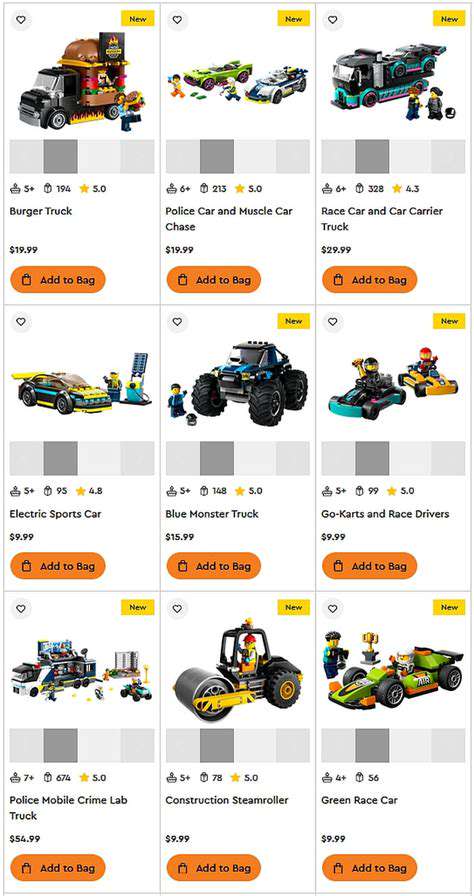

Utilizing Specialized LEGO Minifigures and Accessories

LEGO minifigures and accessories are more than just decorative elements; they are an integral part of creating immersive and engaging LEGO worlds. Specialized accessories, such as tools, weapons, or even specific outfits, can enhance the storytelling potential of a LEGO creation. The incorporation of minifigures and accessories can transform a simple structure into a dynamic and detailed scene, adding another layer of complexity and engagement to the building process. Careful selection of minifigures and accessories can help convey a specific theme or narrative within your LEGO creation.

Achieving Structural Integrity in Large-Scale Models

Ensuring Foundation Stability

A robust foundation is crucial for any structure to withstand the stresses of time and environmental factors. Proper soil analysis and geotechnical investigations are critical in identifying potential weaknesses and ensuring that the foundation design effectively addresses these vulnerabilities. This includes considering factors such as soil type, water table fluctuations, and potential seismic activity. Careful selection of foundation materials, such as concrete or pilings, and meticulous construction techniques are essential to prevent settlement and maintain long-term stability.

Adequate bearing capacity of the ground beneath the foundation is paramount. Understanding the load-bearing capacity of the soil is critical for designing a foundation that can safely support the entire structure's weight and anticipated loads. This calculation must consider not only the current load but also potential future increases in weight or use.

Designing for Load Distribution

Effective structural design necessitates a thorough understanding of how loads are distributed throughout the structure. This includes considering the weight of the building materials, anticipated use of the building, and potential external loads like snow, wind, or earthquakes. Properly distributing these loads across the structure's components prevents localized stress concentrations that could compromise the overall integrity.

Careful consideration must be given to the distribution of live and dead loads. Live loads, such as the weight of occupants and furniture, can vary greatly, while dead loads represent the permanent weight of the structure itself. Designing for both types of loads is essential to ensure the structure can withstand the anticipated stresses throughout its lifespan.

Utilizing Appropriate Materials

The selection of building materials plays a significant role in achieving structural integrity. Materials must be chosen based on their specific properties, including strength, durability, and resistance to environmental degradation. Factors like fire resistance, moisture absorption, and resistance to corrosion must be carefully considered.

Using high-quality materials with certified properties is essential for reliable structural performance. Specifications and standards must be adhered to meticulously to ensure consistent material quality throughout the entire construction process. This helps guarantee the structural integrity of the building over its intended lifespan.

Implementing Robust Connections

Strong and reliable connections between structural elements are critical for distributing loads effectively and preventing failures. Properly designed connections ensure that forces are transferred safely and efficiently throughout the structure. Carefully executed welding, bolting, or other connection methods are essential to guarantee the structural integrity.

Considering Environmental Factors

Environmental factors can significantly impact the structural integrity of a building. Factors such as temperature fluctuations, moisture, and exposure to harsh weather conditions can cause deterioration of materials and weakening of structural elements. Careful consideration of these factors in the design phase is crucial to mitigate these potential issues.

Protecting the structure against environmental degradation is a crucial aspect of ensuring long-term structural integrity. Implementing appropriate waterproofing measures and designing for thermal expansion and contraction are examples of proactive measures that can extend the lifespan of the structure.

Employing Advanced Structural Analysis

Advanced structural analysis techniques can provide valuable insights into the behavior of complex structures under various loading conditions. Sophisticated computer modeling and simulations allow engineers to evaluate potential weaknesses and optimize design choices for enhanced structural integrity. This can help predict the response of a building to unforeseen events.

Utilizing advanced computational tools allows for a more detailed understanding of the structural response under different scenarios. This enables engineers to identify potential vulnerabilities and refine designs to enhance the overall structural integrity of the building.

Regular Inspections and Maintenance

Regular inspections and maintenance are essential to ensure the continued structural integrity of a building. These inspections help identify potential problems early on, preventing costly repairs or catastrophic failures later. Thorough inspections allow for proactive measures to be taken to address deterioration or damage. This is particularly crucial for older buildings or those in high-risk areas.

Implementing a robust maintenance schedule is crucial for the longevity of a building. Routine maintenance tasks, such as inspections and repairs, can significantly extend the lifespan of the structure and avoid costly and time-consuming repairs or replacements in the future. This includes addressing any issues related to corrosion, cracks, or structural deformations as they arise.

Read more about Guide to Building Advanced Lego Structures

Hot Recommendations

-

*Best Sci Fi Books to Read in 2025

-

*How to Start a Reading Journal

-

*Guide to Collecting Vinyl Records by Genre

-

*Guide to Self Publishing Your Book

-

*Guide to Reading More Books

-

*How to Solve a Megaminx Fast

-

*Guide to Identifying Edible Plants While Hiking (Use Caution!)

-

*How to Solve a 5x5 Rubik's Cube

-

*Guide to Building Advanced Lego Structures

-

*How to Capture Star Trails Photography

![Best Photography Editing Software [2025]](/static/images/34/2025-07/GIMP3AAFreeandOpen-SourceOption.jpg)