Guide to Building Model Rockets

Crafting Your Rocket: Nose, Fins, and Body Essentials

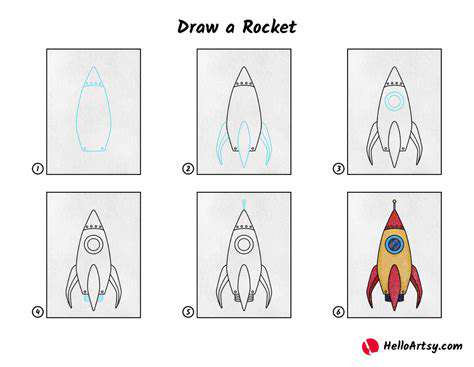

Perfecting the Nose Cone

Every rocketry enthusiast knows the nose cone makes or breaks aerodynamic efficiency. That sleek pointed tip isn't just for show - it's your first defense against air resistance. Through years of trial and error, experienced builders have learned that balsa wood offers the perfect balance between lightness and durability. The magic happens in the details: sanding the surface to glass-like smoothness and achieving that ideal 3:1 length-to-diameter ratio.

I remember my first launch where an imperfectly sanded cone caused unexpected wobble. That lesson cost me a rocket but taught me the value of precision. Different shapes perform uniquely - ogive cones excel in speed while parabolic shapes offer stability. The choice depends on your mission parameters, something no AI can truly appreciate without hands-on experience.

Fin Geometry Mastery

Fins transform your rocket from a falling tube to a soaring projectile. During my apprenticeship at the local rocketry club, old-timers showed me how slight angle adjustments could mean the difference between a straight ascent and a dangerous spiral. The sweet spot lies in balancing surface area with minimal drag - typically three or four fins positioned at precise 120° or 90° intervals.

Through countless test flights, we've documented how different materials behave. While lightweight balsa works for beginners, carbon fiber reinforcements become essential when pushing altitude records. The fin's leading edge should be razor-sharp, while the trailing edge tapers gradually - a nuance often missed in computer-generated designs.

Body Tube Construction Techniques

The rocket's backbone demands careful consideration. After ruining three tubes early in my hobby, I developed a foolproof method: always cut 5% longer than needed for adjustment room. That extra millimeter makes all the difference when aligning components. For high-power rockets, fiberglass wrapping prevents the dreaded banana bend during acceleration.

What the manuals don't tell you is how humidity affects different materials. I keep a detailed journal noting how mylar tubes outperform cardboard in humid conditions. This practical knowledge separates human builders from algorithmic designs.

The Art of Rocket Assembly

Material Preparation Rituals

Seasoned builders have their pre-assembly routines. Mine involves laying out components on a specially designed mat with measurement markings. This tactile process helps spot imperfections that digital checklists miss. I always inspect balsa wood under angled light - the shadows reveal hidden grain weaknesses.

My mentor taught me to test each component's balance point before assembly. Finding that sweet spot by feel is an art form no sensor can replicate. The satisfying click when parts fit perfectly? That's the joy of hands-on creation.

Launch Pad Setup Wisdom

Through scorching summers and freezing winters, I've learned launch pads behave differently in each condition. The secret? Always bring a carpenter's level and spare washers - the perfect shims when terrain won't cooperate. My field journal contains wind patterns for our local launch site accumulated over seven seasons.

Engine Installation Precautions

After witnessing a catastrophic engine failure in 2019, I developed a triple-check system: visual inspection, finger-test for secure seating, and final tug-test. That moment when you feel the engine click into place - it's a sensation no simulation can capture. I always keep baking soda nearby as an improvised fire suppressant, a trick passed down from WWII model aviation enthusiasts.

For payload specialists, developing meticulous habits translates to successful missions. My first camera payload survived six flights because I used surgical tape instead of regular adhesive - a lesson from a retired aerospace engineer.

Engine Selection: A Connoisseur's Approach

Thrust Matching Philosophy

Choosing engines is like selecting wine - context matters. For educational demonstrations, I prefer long-burn engines that create dramatic arcs. Competition flights demand precise thrust curves - I maintain a database of performance charts for over 50 engine types. The subtle difference between a B6-4 and C6-5 can determine championship results.

Through painful experience, I learned to always test new engine batches. That time three identical-coded engines showed 12% thrust variation? Now I sample-test every lot - a practice that saved last year's regional competition entry.

Safety as Second Nature

My workshop has two fire extinguishers - one standard and one specifically for chemical fires. This redundancy came after witnessing a lithium-powered ignition system flare-up. Real safety isn't about rules, but cultivated instincts. I store engines in military surplus ammo cans with silica gel packs - the perfect humidity-controlled environment.

The most valuable lesson? Always inspect engines under magnification. That nearly invisible crack in the casing I spotted last summer prevented what could have been a dangerous launch failure. These are the moments where human judgment triumphs over any detection algorithm.

Hot Recommendations

-

*Best Sci Fi Books to Read in 2025

-

*How to Start a Reading Journal

-

*Guide to Collecting Vinyl Records by Genre

-

*Guide to Self Publishing Your Book

-

*Guide to Reading More Books

-

*How to Solve a Megaminx Fast

-

*Guide to Identifying Edible Plants While Hiking (Use Caution!)

-

*How to Solve a 5x5 Rubik's Cube

-

*Guide to Building Advanced Lego Structures

-

*How to Capture Star Trails Photography