Raku Firing Pottery Explained

Raku firing is a unique and exciting pottery technique that involves a rapid reduction firing followed by a controlled cooling process in a sealed container. This process results in a distinctive range of colors and textures, often with unpredictable results that contribute to the appeal of the technique. Understanding the materials used in Raku firing is crucial for achieving the desired outcomes and for safety considerations.

Clay Bodies for Raku Firing

Not all clay bodies are suitable for Raku firing. The clay must possess a certain level of plasticity and be able to withstand the rapid temperature fluctuations and chemical reactions that occur during the firing process. Some clays, particularly those with high iron content, can develop beautiful colors during Raku firing. Choosing the right clay is critical for the desired outcome, as different clays react differently to the firing conditions.

High-fire clays, often used in traditional kiln firing, are generally not well-suited for Raku. The rapid heating and cooling cycles can cause cracking and warping in these clays, leading to unsatisfactory results.

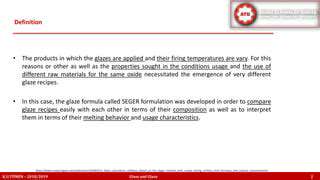

Glazes and Their Role in Raku

Glazes play a significant role in Raku firing, adding both aesthetic appeal and protection to the finished piece. Raku glazes are often specifically formulated to withstand the unique conditions of the firing process. The rapid cooling process can cause unusual surface effects, creating interesting textural patterns on the glaze. The chemistry of the glazes and the clay body will determine the final color and appearance of the piece.

The Importance of Kiln Atmosphere

The kiln atmosphere during the Raku firing process is critical for the final results. A reduction atmosphere, which is low in oxygen, is often used to create the distinctive colors and textures. Understanding how the oxygen levels affect the firing process is key to controlling the outcome. The temperature fluctuations and the reduction atmosphere can create a variety of colors and patterns, leading to unique and unpredictable results.

Supporting Materials for Raku Firing

While clay and glaze are central, supporting materials are crucial for a successful Raku firing. These often include specialized Raku-specific containers, often made of metal or ceramic, that are used to control the cooling process. The careful selection of these materials is vital, as they are often exposed to very high temperatures and must be able to withstand the rapid temperature fluctuations. These containers play a significant role in the final appearance of the piece.

Safety Precautions in Raku Firing

Raku firing involves high temperatures and potentially dangerous materials. Understanding the safety precautions for handling the materials and the firing process is essential. The materials used in the kiln, like the kiln itself, need to be carefully considered and handled with the appropriate safety equipment. Always follow instructions from the source and from experienced Raku practitioners. Safety is paramount.

The Impact of Materials on the Final Product

The interaction of the various materials used in Raku firing—the clay, glaze, and supporting materials—directly impacts the final product. Choosing the right clay body, glaze, and kiln atmosphere are all critical elements in achieving the desired aesthetic and functional outcomes. The unique combination of these materials creates the distinctive look and texture associated with Raku pottery. Understanding the interplay of these materials leads to more predictable and satisfying results.

Minimalism is a lifestyle choice that emphasizes simplicity and intentionality. In a world filled with constant distractions, adopting a minimalist approach can provide significant mental clarity. By reducing physical clutter, individuals often find that their mental clutter diminishes as well.