Pottery Glazing Techniques

Understanding the Fundamentals of Dip and Pour Techniques

Becoming proficient in dipping and pouring isn't just about moving liquids from one place to another. It demands a deep appreciation for the interplay between texture, temperature, and timing. These core principles serve as the foundation for countless culinary and artistic pursuits. When you grasp these elements, you'll achieve reliable, professional results with every attempt.

The approach must vary depending on what you're working with. A light vinaigrette behaves completely differently than a rich chocolate ganache. Recognizing these distinctions makes all the difference in achieving that perfect finish.

Choosing the Right Tools for the Job

Your equipment selection directly influences your success. The proper implements transform messy attempts into graceful executions. Whether you need a narrow-tipped squeeze bottle for delicate drizzles or a wide-mouth funnel for bulk transfers, matching your tools to the task prevents frustration and waste. This thoughtful preparation pays dividends in both quality and efficiency.

Controlling Temperature and Viscosity

Heat and thickness aren't just details - they're make-or-break factors. Ingredients behave differently when warm versus cold, and this affects everything from application to final setting. Monitoring thermal conditions isn't optional; it's the difference between a glossy finish and a ruined project. That caramel sauce might look perfect at 180°F, but at 200°F it could scorch.

Viscosity requires similar attention. Thin liquids demand quick, confident movements, while thicker mixtures need deliberate, controlled application. Recognizing these requirements separates amateurs from professionals.

Practicing Consistency and Precision

Repetition builds muscle memory and confidence. Working with various materials trains your hands to adapt instinctively. That uniform coating you admire on professional pieces comes from hundreds of hours refining technique. There's no substitute for hands-on experience when developing this level of control.

Accuracy matters just as much as repetition. When measurements and applications become second nature, your results gain that polished, intentional quality customers expect. This precision transforms good work into exceptional craftsmanship.

Troubleshooting Common Issues

Even experts encounter challenges. Streaks, bubbles, or uneven coverage test every creator's patience. The solution lies in systematic observation - noting what changed when problems appear. Keeping detailed records turns failures into valuable learning opportunities.

Developing this analytical approach builds resilience. Each solved problem adds to your repertoire, making you more adaptable when new challenges arise during complex projects.

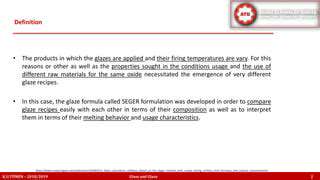

The Importance of Glaze Formulation and Firing

Glaze Formulation: A Fundamental Aspect of Ceramics

Creating ceramic glazes resembles alchemy, where raw materials transform through fire into lustrous surfaces. This metamorphosis depends entirely on the careful balance of ingredients. Getting the formula right means the difference between a durable finish and a disappointing flake-off.

The magic happens in the recipe - each component contributes specific qualities that combine to create something greater than the sum of its parts. Like a master chef, the ceramicist must understand how each ingredient behaves under heat.

Understanding the Role of Raw Materials

Silica isn't just sand - it's the glass-forming backbone of your glaze. Fluxes do more than lower melting points; they determine how the glaze flows and adheres. This complex chemistry requires respect and study.

Some combinations create beautiful reactions, while others produce disappointing results or even damage kiln shelves. That's why experienced potters keep meticulous notebooks tracking every test batch.

Influencing Glaze Color and Opacity

Metallic oxides work their magic in surprising ways. A tiny amount of cobalt can produce vivid blues, while iron might yield anything from honey amber to deep chocolate depending on conditions. These transformations make glaze chemistry endlessly fascinating.

True mastery comes from understanding how these colorants interact with other components and firing conditions. That perfect robin's egg blue might require three different tests to account for clay body interactions.

Impact of Glaze Viscosity on Firing

Glaze behavior during firing makes or breaks a piece. Too fluid, and it runs off the pot; too stiff, and it fails to heal surface imperfections. Finding that Goldilocks zone requires understanding how viscosity changes with temperature.

Durability and Chemical Resistance of Glazes

A beautiful glaze means nothing if it chips or leaches metals. Functional ware demands formulations that withstand daily use while remaining food-safe. This requires careful attention to material sourcing and testing.

The best glazes form an inseparable bond with the clay body, creating surfaces that endure decades of use. Achieving this requires understanding how expansion rates and chemical compositions interact.

Firing Conditions and Glaze Performance

Kilns don't just get hot - they create miniature atmospheres where chemical reactions unfold. Oxidation versus reduction, fast versus slow climbs, hold times - each variable leaves its mark on the finished surface.

Learning to read a firing like a seasoned chef reads a simmering sauce separates hobbyists from professionals. That perfect crystalline formation or subtle color shift often depends on catching just the right moment during cooling.

Hot Recommendations

-

*Best Sci Fi Books to Read in 2025

-

*How to Start a Reading Journal

-

*Guide to Collecting Vinyl Records by Genre

-

*Guide to Self Publishing Your Book

-

*Guide to Reading More Books

-

*How to Solve a Megaminx Fast

-

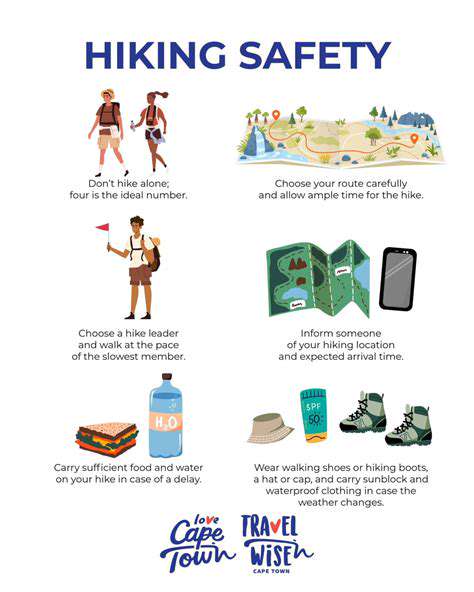

*Guide to Identifying Edible Plants While Hiking (Use Caution!)

-

*How to Solve a 5x5 Rubik's Cube

-

*Guide to Building Advanced Lego Structures

-

*How to Capture Star Trails Photography