Guide to Making Soy Candles at Home

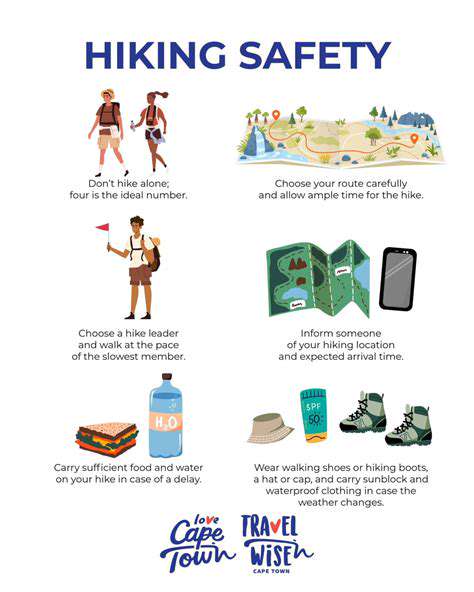

Safety should always be a top priority during any DIY project. Wearing appropriate safety gear can prevent injuries and protect you from potential hazards. Eye protection, such as safety glasses or goggles, is crucial for safeguarding your eyes from flying debris or harmful substances.

Gloves and sturdy work boots provide protection for your hands and feet. These essential safety precautions can significantly reduce the risk of cuts, burns, or other injuries, enabling a safer and more productive work environment.

Materials for Construction

Selecting the right materials is just as crucial as choosing the right tools. The appropriate materials for your project will determine the longevity, strength, and aesthetic appeal of your work. Careful consideration of factors such as durability, water resistance, and aesthetic properties is essential.

Adhesives and Sealants for Finishing Touches

Using the right adhesives and sealants can significantly enhance the quality and longevity of your DIY projects. Choosing the appropriate adhesive for the materials you're working with is paramount for a strong and reliable bond. Proper sealing can also prevent moisture damage and enhance the overall aesthetic appeal.

Power Tools for Efficiency

Power tools can significantly increase the efficiency and speed of many DIY tasks, particularly when dealing with larger projects or materials. However, understanding how to use power tools safely and correctly is crucial to avoid accidents. Using power tools responsibly can dramatically change your approach to projects.

Organization and Storage for Efficiency

Maintaining a well-organized workspace is essential for any DIY enthusiast. Proper storage and organization can save you time and effort, ensuring that tools and materials are readily available. This will also minimize the risk of accidents and damage to tools or materials. A dedicated workspace with clearly designated areas for storing tools and materials will contribute significantly to the overall efficiency and productivity of your projects.

Thorough cleaning and disassembly are essential for a flawless transformation. Remove all unnecessary components, including air filters, spark plugs, and hoses, to create a clean canvas for the upgrades. This step isn't just about aesthetics; it allows for a proper inspection of the engine's health and ensures that any potential issues are addressed before the transformation begins.

Crafting Perfect Candles: Melting, Pouring, and Finishing Touches

Melting the Wax

The melting process is crucial for achieving a smooth, even candle pour. Begin by carefully selecting your wax – soy, beeswax, paraffin, or a blend – and ensuring it's stored in a cool, dry place. Improper storage can lead to inconsistent melting, resulting in a less-than-perfect final product. Use a double boiler or a microwave-safe container for melting, ensuring the wax never comes into direct contact with heat to prevent scorching. Stir the wax frequently during the melting process to ensure even temperatures and avoid the formation of hot spots. This method helps distribute the heat evenly throughout the wax, preventing uneven melting and potential lumps in the final candle.

Precise temperature control is essential. Overheating the wax can cause it to become too liquid, making it difficult to pour and potentially leading to imperfections in the finished candle. Conversely, under-melting can result in the wax being too thick and creating difficulties during the pouring stage. Using a thermometer to monitor the wax's temperature is highly recommended to maintain consistent melting and ensure the wax is at the ideal pouring temperature for your chosen container. A precise temperature range will ensure a clean and even pour.

Pouring the Perfect Candle

Pouring your melted wax into the prepared candle molds is a delicate process that requires careful handling. Ensure the molds are clean and dry before pouring the wax, as any residual materials can affect the final candle's appearance and potentially cause problems during the curing process. Slowly pour the wax into the molds, avoiding excessive splashing or agitation. Pouring slowly allows the air bubbles to escape, contributing to a clear and flawless candle. Taking your time during this step is crucial to achieving a professional-looking finished product. Be mindful of the pouring temperature to prevent the wax from hardening prematurely in the molds.

Careful consideration must be given to the pouring technique. Avoid excessive pressure when pouring, as this can cause the wax to overflow or create unwanted ripples in the surface. Gentle, even pouring is key to achieving a smooth and visually appealing candle. Pouring in a controlled manner, while taking care not to create any air pockets in the wax, will lead to a high-quality candle that will burn evenly and beautifully.

Finishing Touches and Curing

Once the wax has been poured, allow the candles to cool completely and harden. This crucial step ensures that the wax has set properly and that the candle is ready for its final touches. Different wax types have different cooling times, so it's essential to consult the instructions specific to the wax you're using. Careful observation of the cooling process is critical; if the wax begins to cool unevenly, it could lead to imperfections in the final product. Waiting for the wax to fully set is crucial for a successful candle. Allowing the candle to cure completely will create a candle that is ready to burn safely and beautifully.

Adding finishing touches, such as wicks, fragrances, or decorative elements, is the final step in the candle-making process. Properly trimming the wicks to the recommended length is essential for a clean burn. Overly long wicks can cause smoking and uneven burning, while wicks that are too short may not burn correctly. The selection of fragrances is another crucial element that can enhance the overall experience and appeal of the finished product. Using high-quality fragrance oils that are compatible with your chosen wax type is essential for producing a pleasant aroma and avoiding any negative reactions with the candle's materials. Consider the scent's intensity and how it might complement the overall aesthetic of the candle.

![How to Write a Novel [Step by Step]](/static/images/34/2025-05/5FinalTouches3AFormatting2CProofreading2CandPublication.jpg)